Making Best Use Of Safety And Security With Booster Flow & Hydrostatic Stress Examining

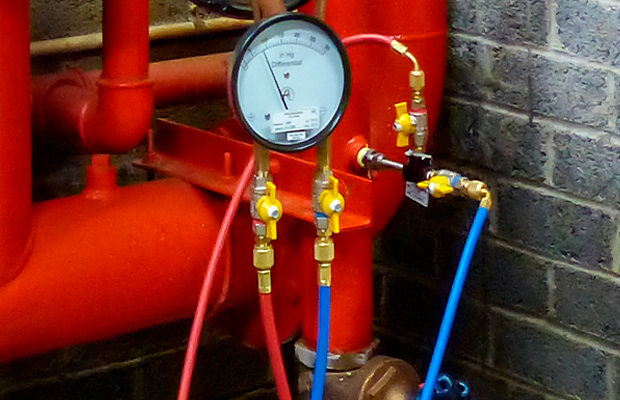

Hydrostatic stress testing is an essential process that is essential in guaranteeing the security and reliability of a large range of devices, structures, and systems. This process involves subjecting tools or frameworks to a specific pressure degree using a liquid, usually water, to examine their structural integrity and also recognize any potential weak points or flaws that can endanger their safety and security and also integrity.

Hydrostatic stress testing has come to be an integral part of quality assurance and also security methods across different industries, consisting of oil and also gas, building and construction, aerospace, as well as manufacturing. Along with hydrostatic pressure testing, booster flow testing is another strategy made use of to examine the efficiency and integrity of tools and also systems. This short article will check out the benefits of both hydrostatic pressure screening and also booster flow testing and also just how they aid make best use of safety and dependability.

What Is Hydrostatic Stress Evaluating?

Hydrostatic stress testing involves subjecting a framework or equipment to a fluid at a specific stress degree to evaluate its capacity to endure the needed load with no failure or leak. The examination is conducted making use of water or various other ideal liquids, such as hydraulic fluid or oil, relying on the kind of devices or framework being evaluated.

The test is conducted by filling up the equipment or structure with the test liquid and also pressurizing it to the required degree for a certain duration. During this duration, any type of defects or leakages in the equipment or framework can be identified as well as rectified, therefore ensuring that it is secure as well as trusted for its desired use.

Advantages Of Hydrostatic Stress Evaluating

Ensures Structural Integrity

One of the primary benefits of hydrostatic pressure testing is that it aids to ensure the architectural honesty of tools as well as frameworks. The examination allows for the recognition of any potential weaknesses, splits, or issues in the tools or structure that might jeopardize its safety as well as reliability.

By recognizing these problems before the tools or structure is put to use, any kind of required repairs or alterations can be made, as well as the tools or framework can be licensed as risk-free for use. This assists to reduce the danger of crashes, injuries, and also tools failure, hence making sure the security of personnel and equipment.

Lowers Downtime As Well As Maintenance Prices

Hydrostatic stress screening helps to reduce downtime and also maintenance expenses by recognizing possible concerns before they cause equipment failing. By identifying any issues or leakages during the screening procedure, repair services can be made prior to the devices or framework is put into solution, lowering the requirement for unscheduled upkeep as well as downtime.

This not only helps to boost equipment reliability however also minimizes the cost of repair and maintenance over the tools's lifecycle, thus improving the tools's overall economic worth.

Complies With Safety Standards As Well As Rules

Hydrostatic pressure testing is a mandatory requirement for lots of markets as well as is typically a regulative demand in particular territories. Compliance with these standards and policies makes certain that the tools or framework satisfies the required safety and security criteria, decreasing the danger of mishaps and also injuries.

In addition, hydrostatic pressure testing aids to preserve compliance with industry-specific https://boosterflowtesting.com.au/ security criteria and also laws, giving guarantee that the tools or framework is safe for usage and decreasing the risk of lawful obligation in case of crashes or injuries.

Boosts Quality Assurance And Quality Assurance

Hydrostatic stress screening is a vital part of quality assurance and quality control processes in lots of markets. By subjecting devices and frameworks to strenuous testing, any type of prospective problems or problems can be identified and addressed prior to the equipment or structure is taken into solution.

This helps to make sure that the equipment or structure meets the necessary high quality requirements, lessening the threat of defects, failures, and also recalls. Furthermore, it helps to improve consumer confidence in the equipment or framework, boosting the organization's reputation and competitiveness out there.

Boosts Equipment Long Life

Hydrostatic stress testing can aid to enhance the durability of devices as well as frameworks by identifying possible problems as well as resolving them prior to they result in equipment failing. By identifying and also fixing any kind of defects throughout the testing procedure, the devices's helpful life can be extended, lowering the demand for early replacements.

Additionally, hydrostatic stress testing aids to maintain the equipment's efficiency and also effectiveness over its life expectancy, lowering the danger of malfunctions and downtime, thus enhancing performance and earnings.

Supplies Accurate And Reliable Data

Hydrostatic pressure testing supplies exact as well as reliable data on the devices or framework's performance, including the ability to withstand the required pressure levels. This information is necessary for evaluating the equipment's performance and determining any prospective concerns that might influence its reliability and also security.

The data produced from hydrostatic pressure screening can additionally be used to notify maintenance and repair routines, making certain that the equipment or framework is kept at optimal degrees to optimize its integrity and security.

Benefits of Booster Flow Testing

Makes Certain Flow Ability

Booster flow testing aids to make certain that tools or systems can satisfy the required circulation capability. By subjecting the equipment or system to the specified circulation price, its performance can be reviewed and also any type of restrictions or inefficiencies can be identified.

Guaranteeing correct flow capacity is important in industries such as oil and also gas, where liquid flow prices are vital for functional performance as well as safety and security. Booster flow testing permits modifications as well as alterations to be made to the tools or system to maximize its flow capability and make sure reliable and also consistent performance.

Recognizes Flow-related Issues

Booster flow testing helps to recognize any flow-related concerns that may impact the efficiency as well as reliability of equipment or systems. This includes issues such as stress decline, circulation instability, cavitation, or insufficient flow circulation.

By identifying these problems during screening, suitable steps can be required to remedy them, making sure smooth operation and stopping possible tools failures or breakdowns.

Verifies Layout as well as Efficiency

Booster flow testing offers validation of the style and also efficiency of tools or systems. By subjecting them to the specified flow prices, their actual performance can be contrasted versus design requirements as well as functional demands.

This validation makes certain that the equipment or system operates as planned and satisfies the needed performance requirements. Any kind of inconsistencies or shortages can be resolved prior to the devices or system is taken into solution, lessening the danger of performance problems or failures in real-world operations.

Maximizes Effectiveness

Booster flow testing helps optimize the efficiency of tools or systems by identifying locations of enhancement in regards to flow capability and also efficiency. By fine-tuning the layout as well as operational criteria based on the examination results, effectiveness can be made best use of, resulting in cost financial savings and also enhanced performance.

Reliable flow systems also lower the danger of devices overloading, which can bring about premature wear, increased https://boosterflowtesting.com.au/fire-booster-flow-testing/ maintenance demands, and also prospective safety dangers. Booster flow testing aids make sure that equipment runs within its intended flow limits, enhancing general system effectiveness as well as long life.

Conclusion

Hydrostatic pressure screening as well as booster flow testing are essential processes that make the most of the safety and dependability of devices, structures, and systems throughout different industries. Hydrostatic pressure testing makes sure structural stability, decreases downtime and also upkeep expenses, complies with safety criteria, improves quality assurance and also guarantee, improves tools long life, and also provides exact data. Booster flow testing, when carried out in conjunction with hydrostatic pressure testing, ensures flow capacity, recognizes flow-related problems, verifies layout and also performance, and also optimizes efficiency.

By carrying out these testing methodologies, industries can mitigate risks, lessen devices failures, and also make certain the secure and trusted procedure of their assets, eventually boosting productivity, productivity, as well as consumer fulfillment.